Metal structure change under the action of torsion fields

After it was discovered that torsion fields can change the structure of crystals (see Fig. 32), experiments were carried out to change the crystal structure of metals. These results were first obtained by the Ukrainian scientist V.P. Mayboroda through the action of dynamic radiation of Akimov’s generator on the molten metal, which was melted in the Tamman furnace.

The experimental setup is shown in fig. 33.

P = 30 mW Time exposure 30 min

Fig.33. Installation for changing the crystal structure of metals, by acting on the melt torsion field

The Tamman furnace is a vertically mounted cylinder 1 made of special refractory steel.Top and bottom of the cylinder is closed with water-cooled lids. The metal case of the cylinder, 1b thick, 5 cm is grounded, therefore no electromagnetic fields can penetrate inside the cylinder. Inside the furnace, metal 4 is poured into the crucible 3 and melted by means of a heating element 5 , for which a graphite tube was used. After the metal has melted, the heating element 5 is turned off and the torsion generator 2 , located 40 cm from the cylinder axis, turns on. The torsion generator irradiates the cylinder for 30 minutes while consuming a power of 30 mW. During 30 min, the metal was cooled from 1400c before 800c

Then it was taken out of the furnace, cooled in air, after which the ingot was cut and its physico-chemical analysis was performed. The results of the analysis showed that the lattice pitch of the metal irradiated with a torsion field changed or the metal had an amorphous structure throughout the ingot volume.

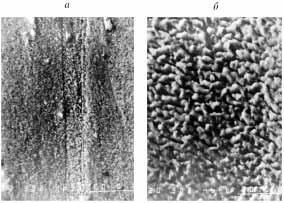

In fig. 34 and presents a sample of tin that has been subjected to torsion irradiation in a molten form.

Fig. З4. The change in the structure of tin (increased. 6000):a – control sample; b – irradiated by a torsion field

It is important to note that the torsion radiation of the generator passed through a grounded metal wall 1.5 cm thick and affected the molten metal. This is impossible to achieve with any electromagnetic fields.

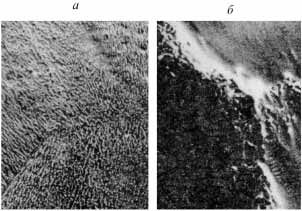

In fig. 35 shows the change in the structure of copper under the action of torsion radiation.

Fig. 35. The microstructure of cast copper (led 100): a – control sample; b – after irradiation with a torsion field

The effect of torsion radiation on the copper melt increases the strength and ductility of the metal. In tab. No. 4 shows the comparative data on the study of plasticity and strength of copper after torsion effects.

Table number 4

| Metal condition | Strength (Etc.) | Plastic (Pl.) | ||

| Control melting | 7.1-7.3 | 12-14 | 13.2-13.4 | 21-22 |

| Processing torsion field | 6.6-7.4 | 21-24 | 15.6-16.7 | 27-31 |

Shipov G.I. The theory of physical vacuum. Part six: “Experimental manifestations of torsion fields”, Section 1 // “Academy of Trinitarianism”, Moscow, El. No. 77-6567,publ.10795, 05.11.2003